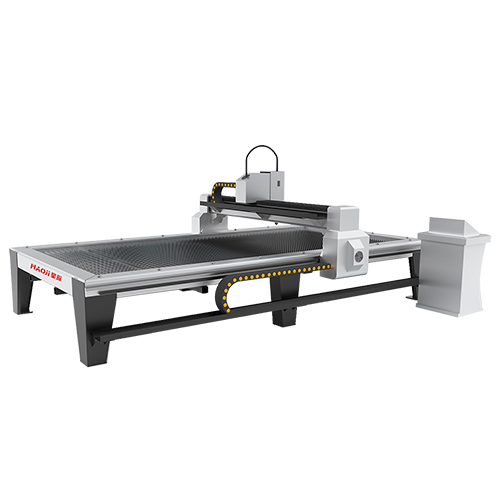

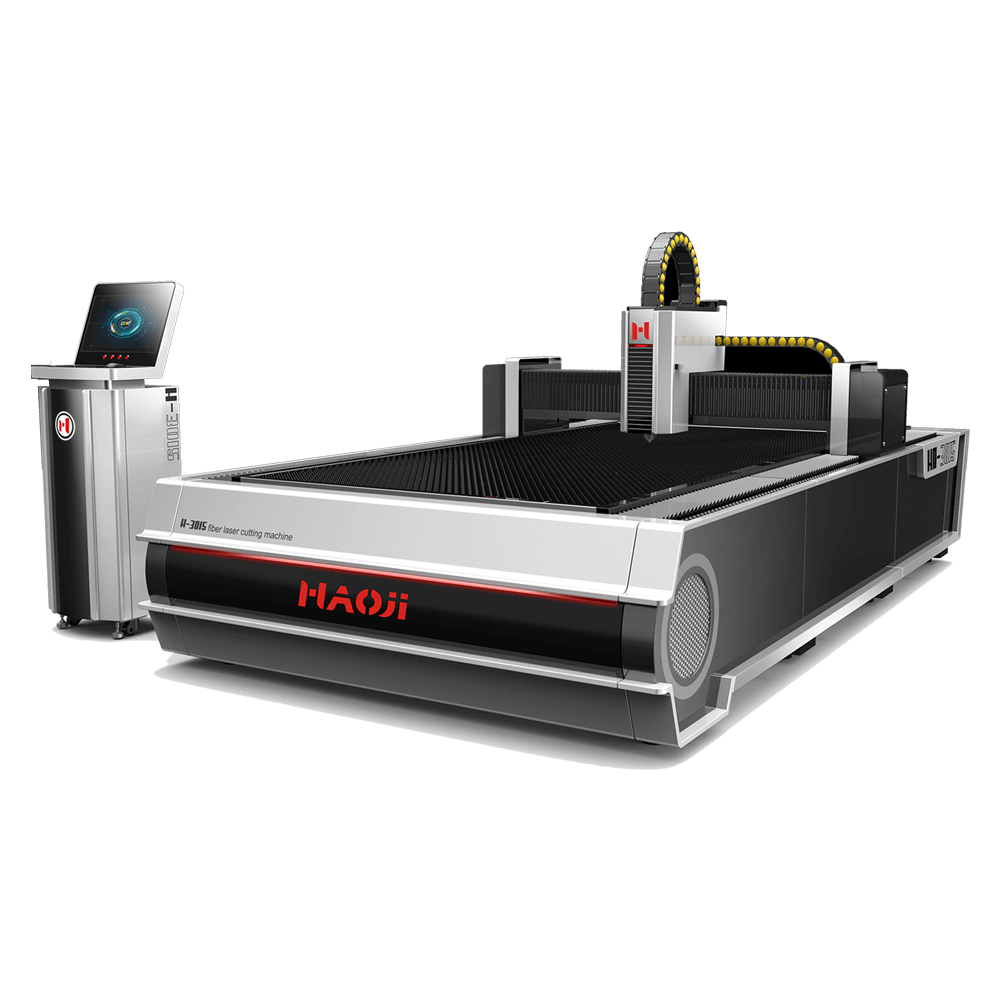

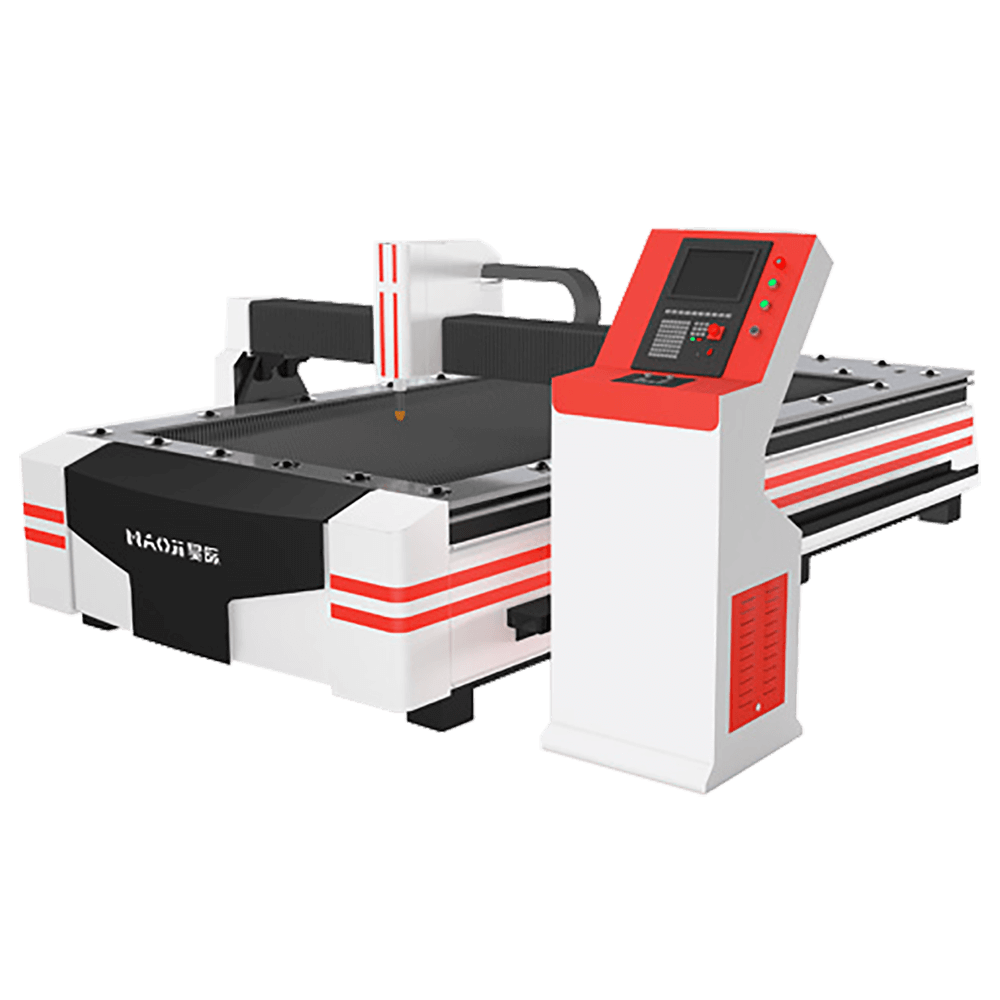

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

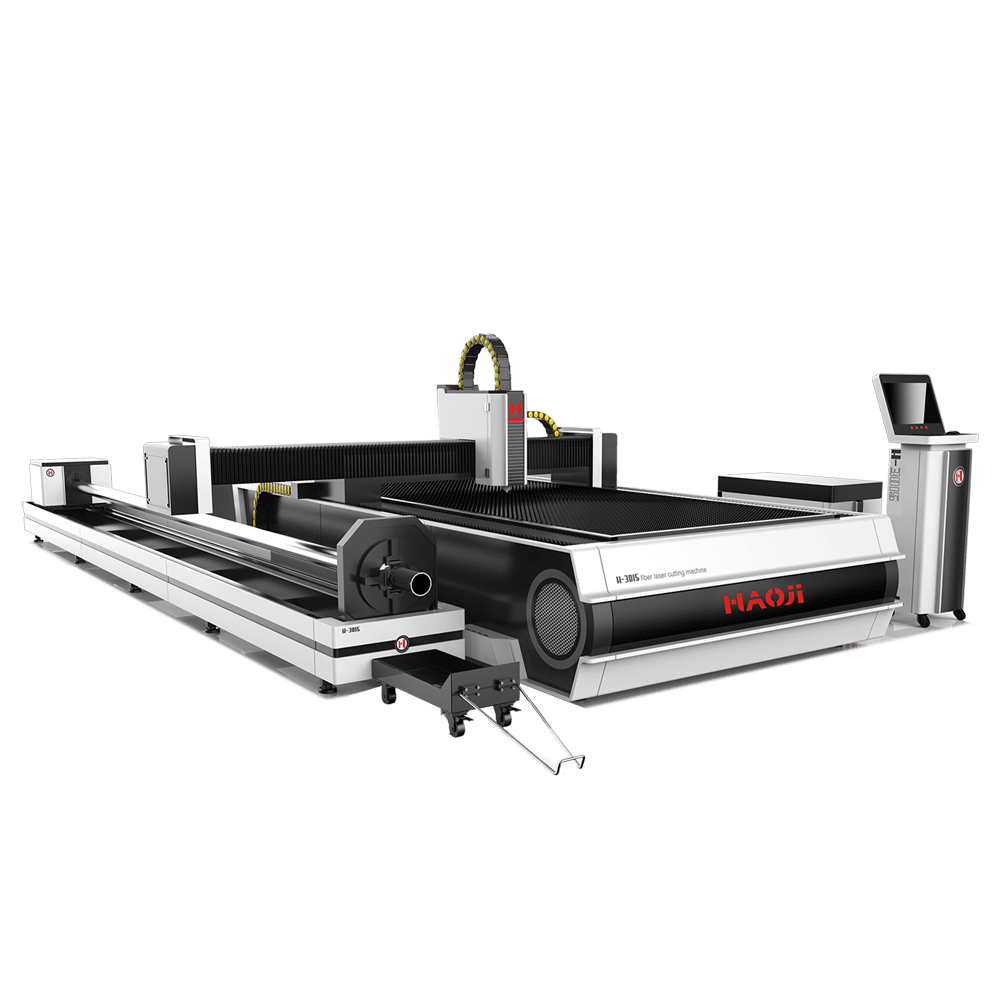

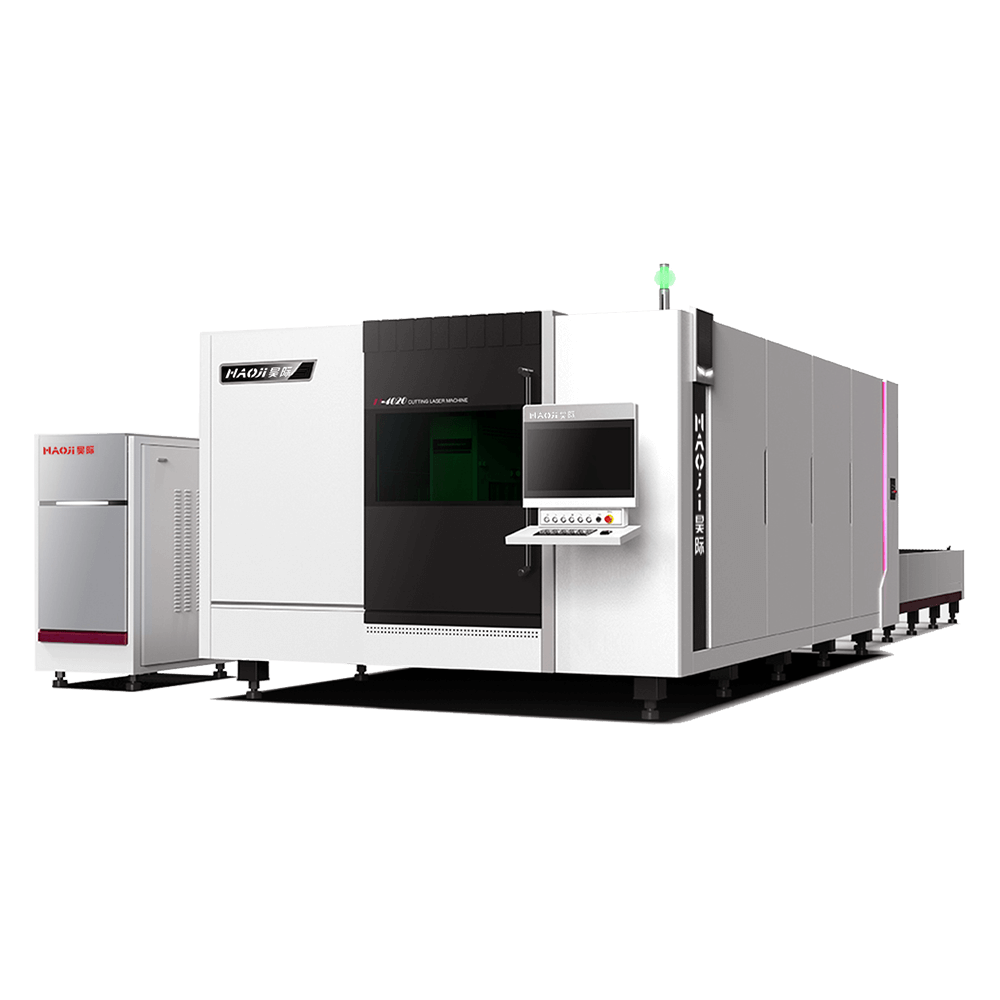

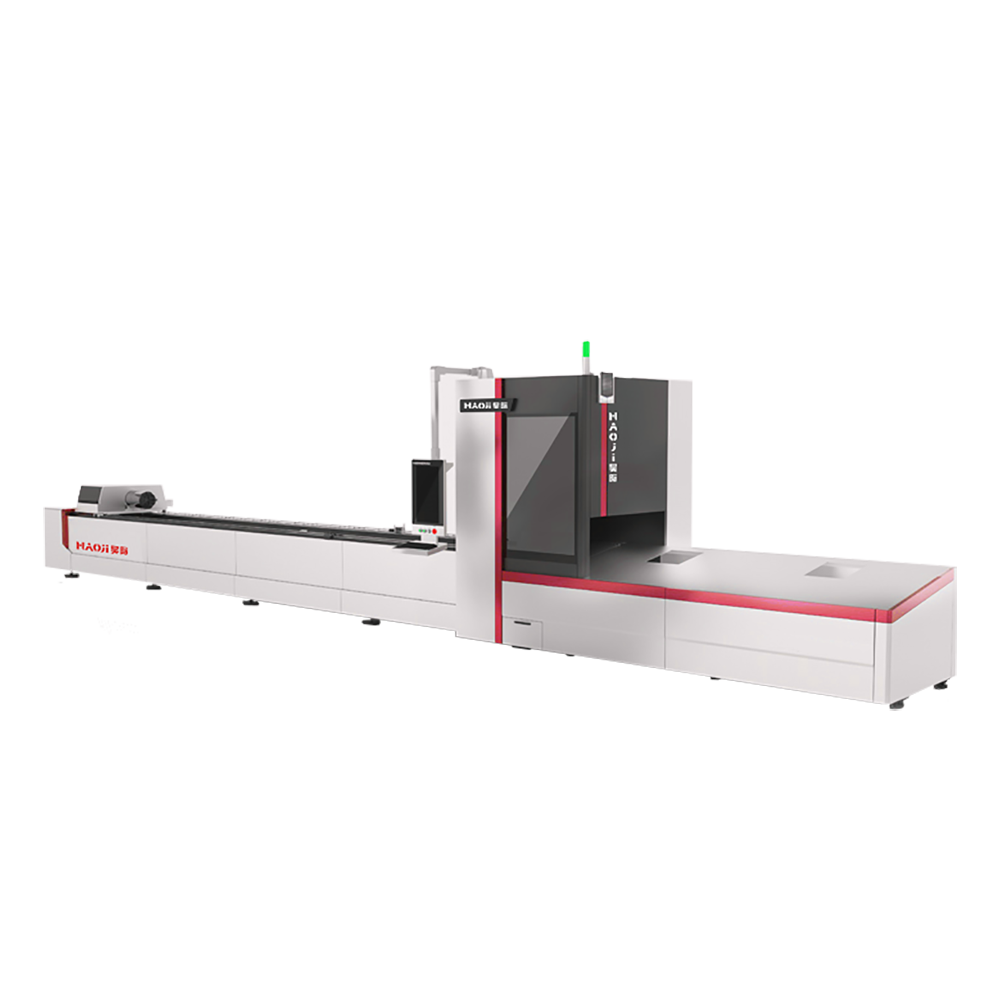

Laser power

1000~20000wMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

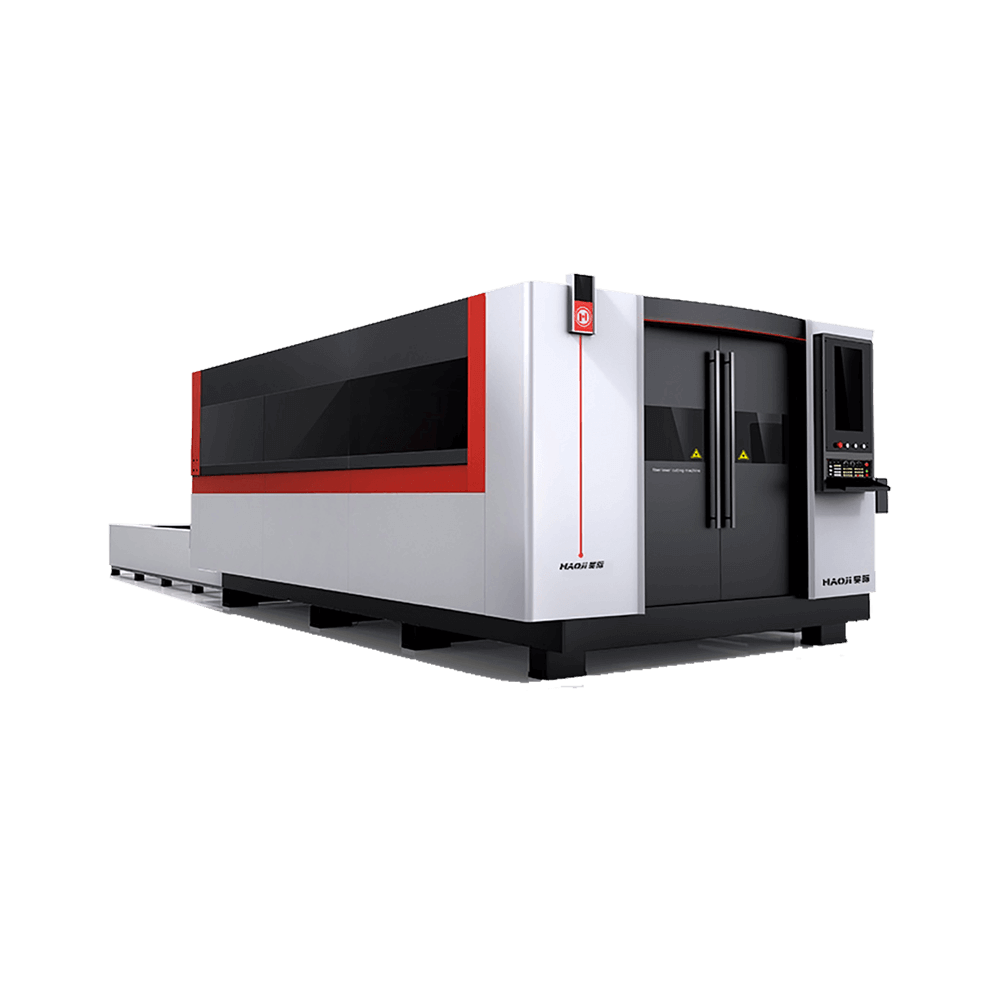

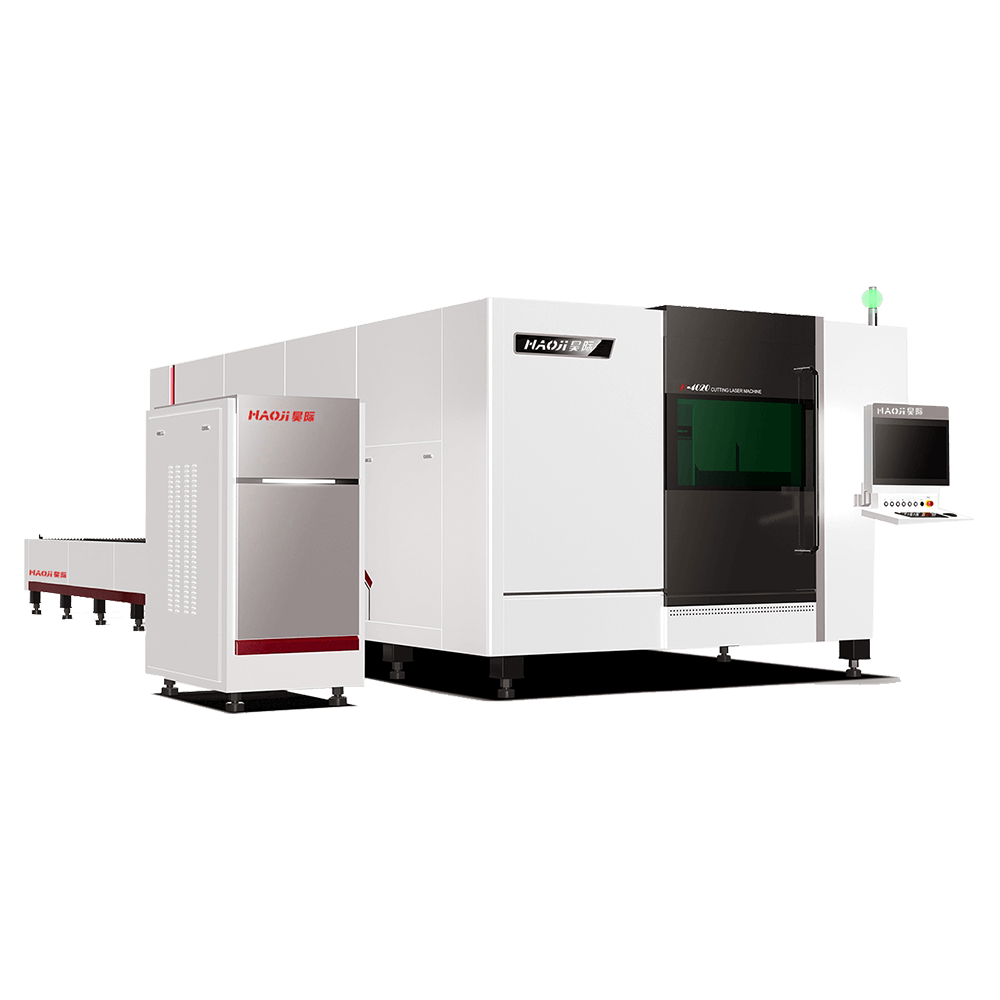

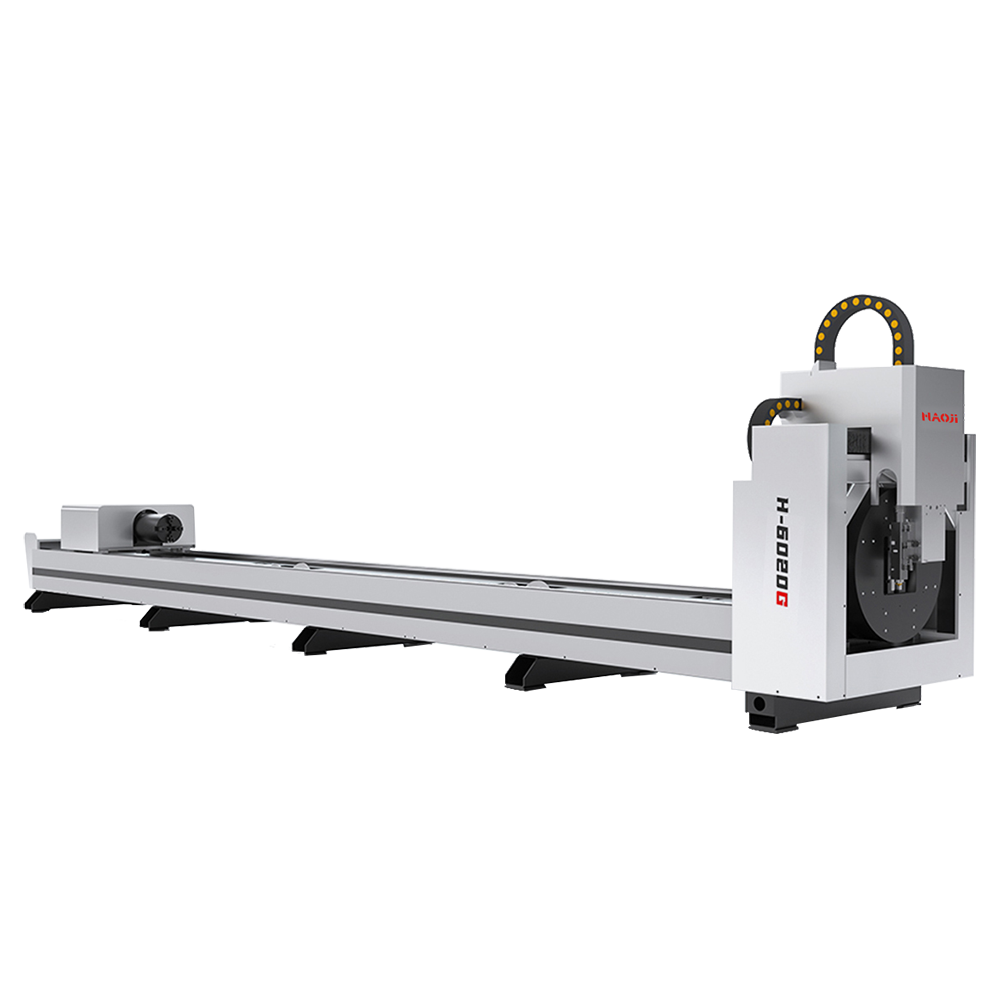

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

10000-35000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

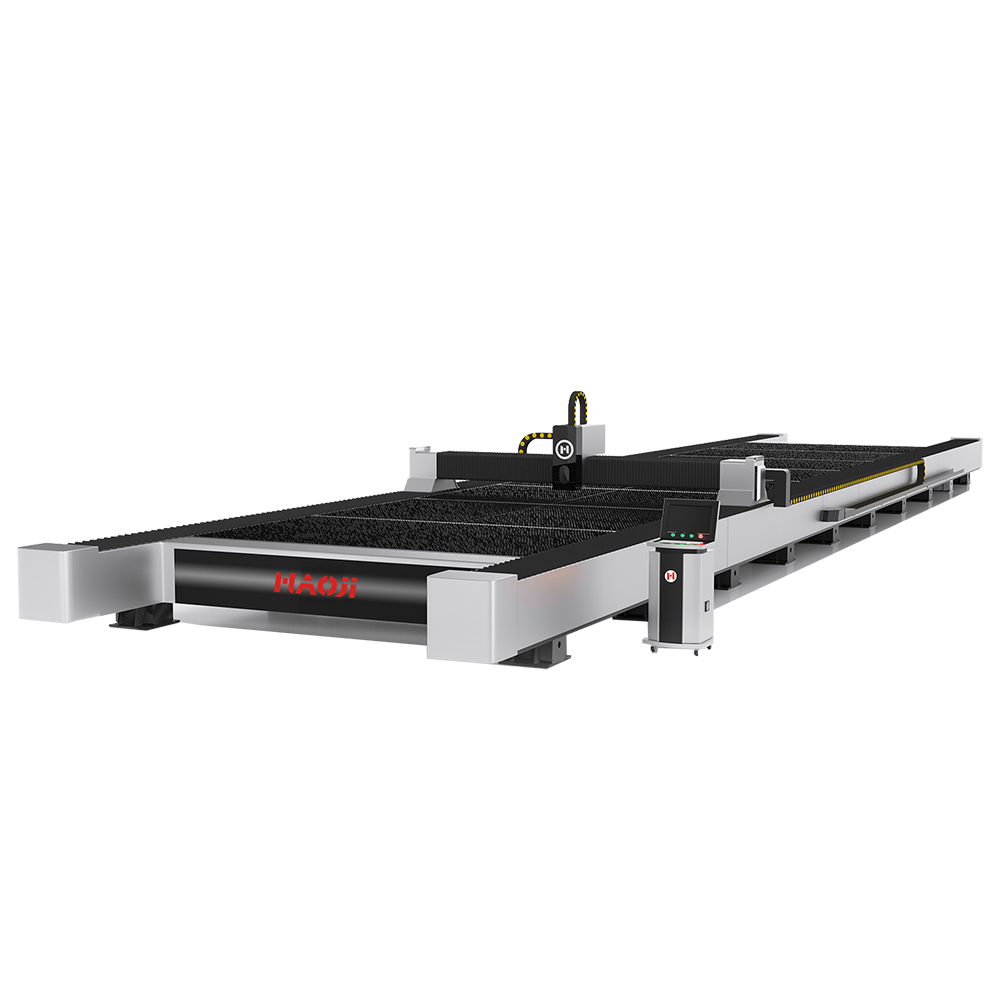

Laser power

1000-20000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-12000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

3000-20000WMax. moving speed

180m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

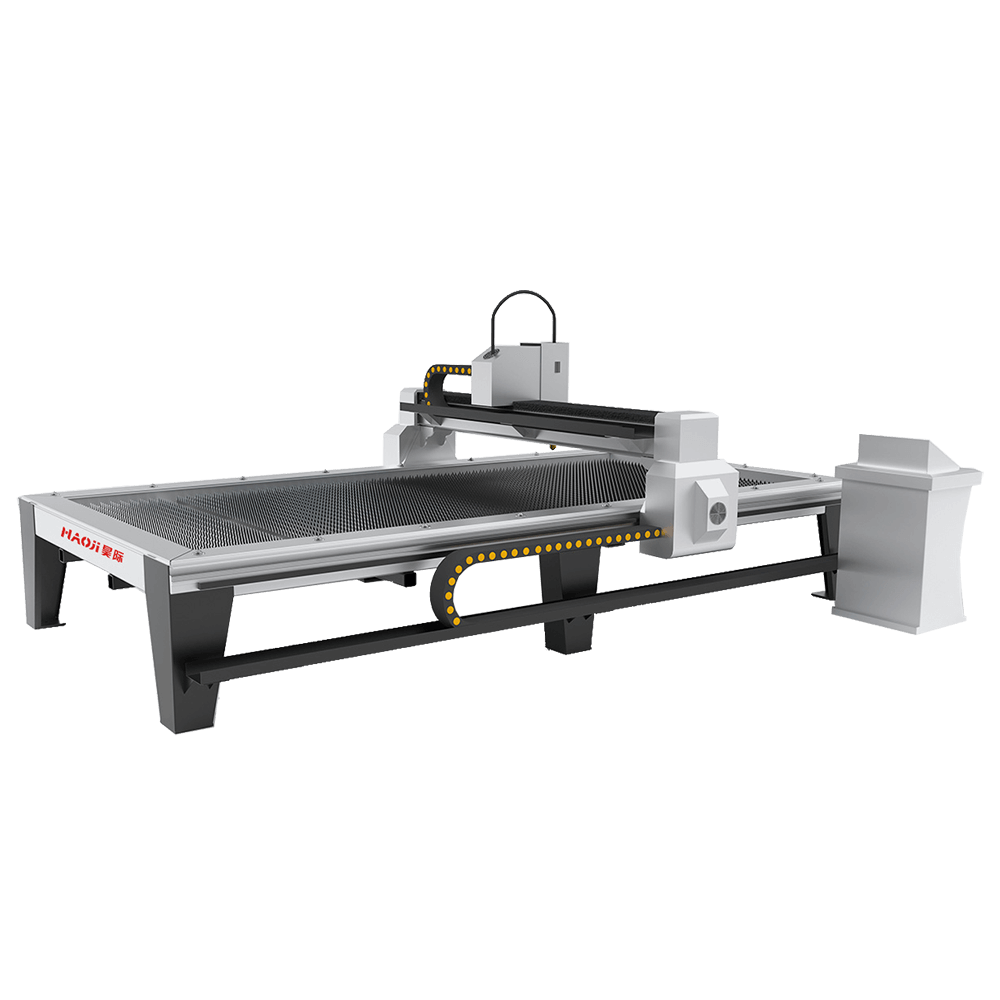

Laser power

/Max. moving speed

100m/minRepeat positioning accuracy

0.03mmBlessing diameter

/

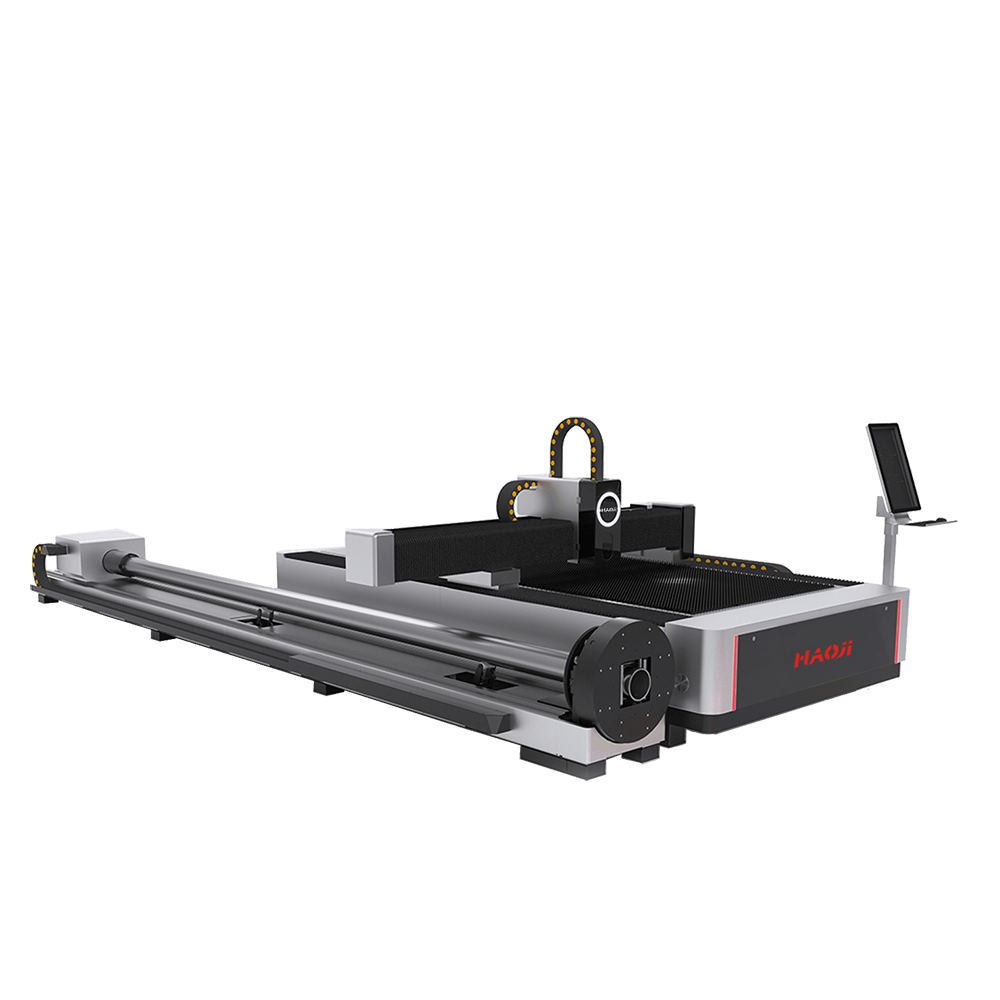

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

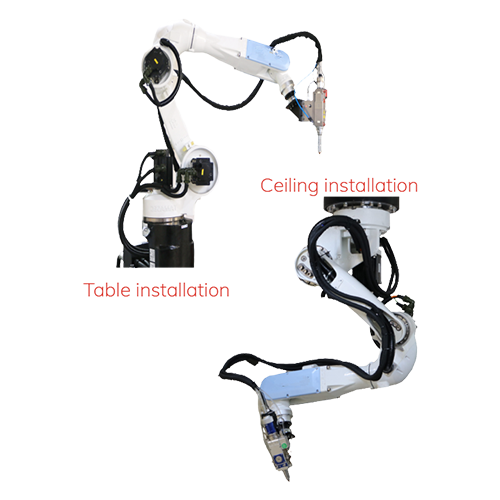

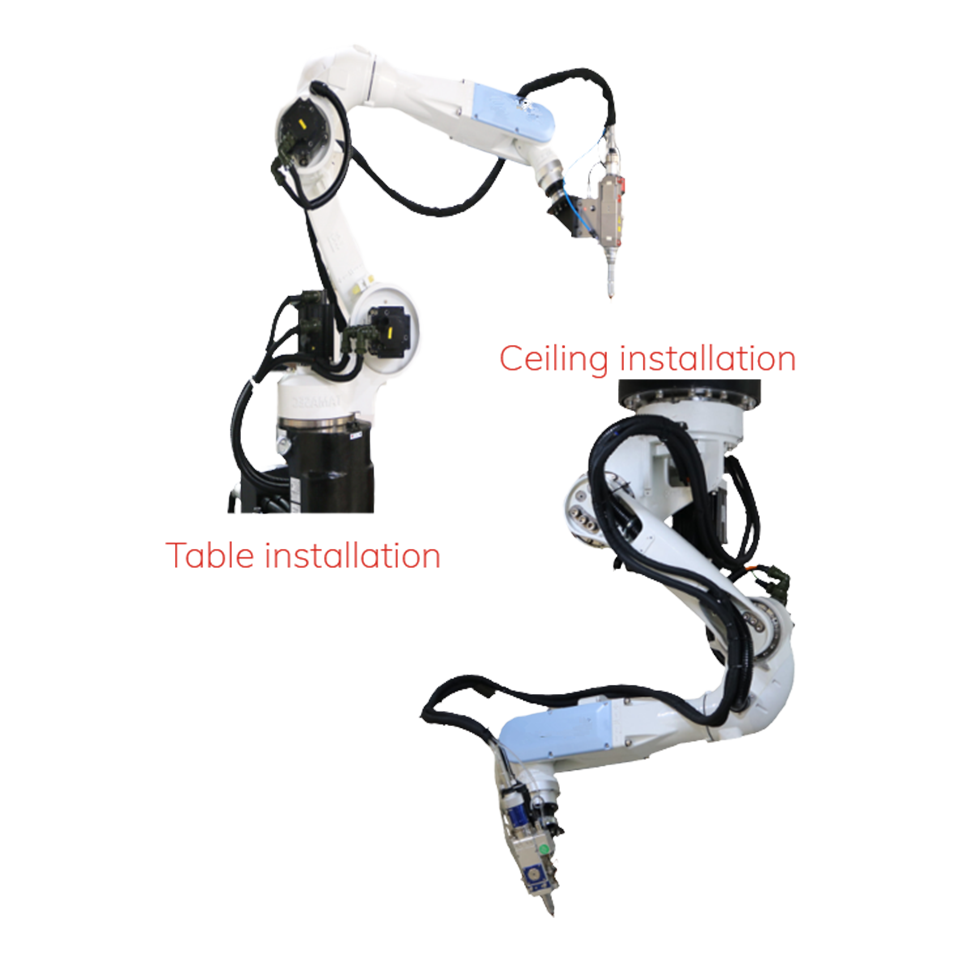

Laser power

1000W-4000WMax. moving speed

140°-600°/sRepeat positioning accuracy

±0.1mmBlessing diameter

/

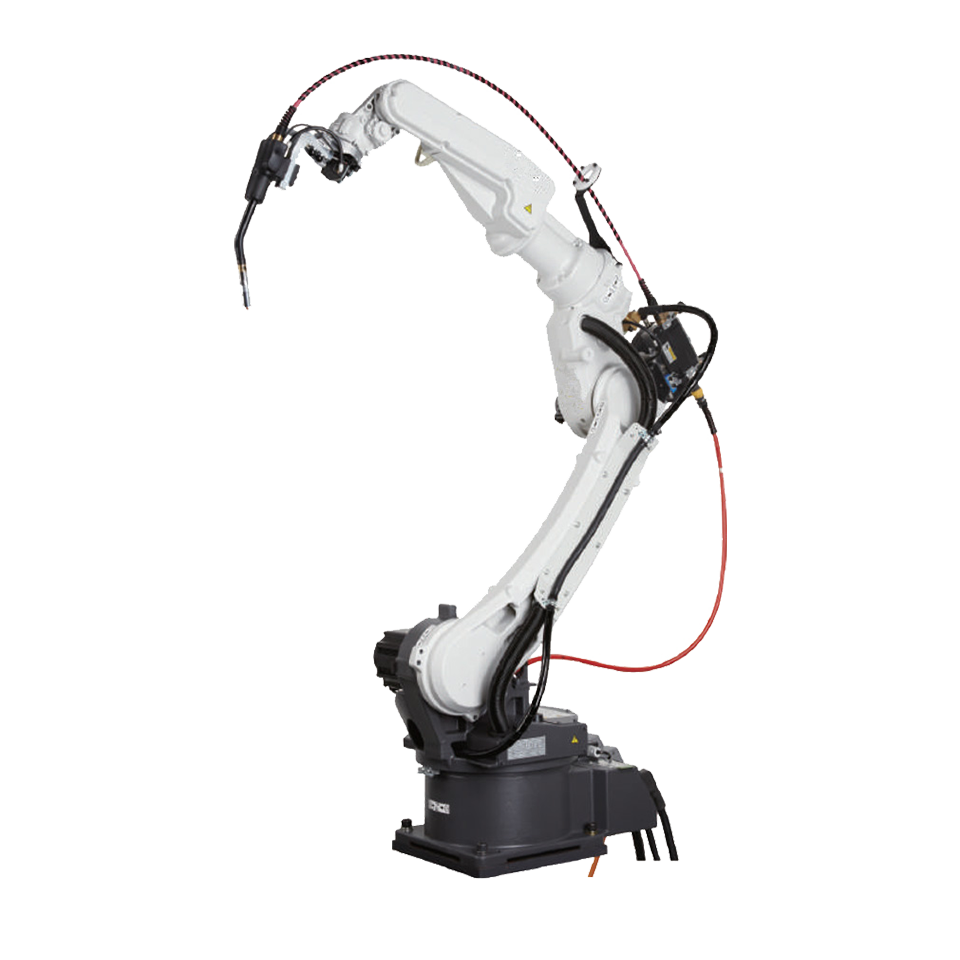

Laser power

1000-3000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-2000WMax. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

/Max. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

TIME:04-03 2022

1. Oxygen & nitrogen: A vaporizer must be added to raise the liquid temperature to normal gas state. The purity of nitrogen and oxygen must be 99.99% and 96.99% respectively. The welded steel pipe must be cleaned before connecting the internal pipes of the machine tool.

2. Air: when high-pressure air is used to cut sheet, please ensure that cutting air is free of oil, water and dust. The air compressor shall be equipped with a cold dryer and three-stage filtering device.

3. Do not replace the air of driving cylinder with oxygen. When air is introduced into cylinder pipe of exchange platform, flying sparks are likely to burn the air pipe. If failing to get it under control, fire may break out internally.

4. The air pressure of driving cylinder must be less than 1MPa. Otherwise, the air pipe will burst.